The textiles industry suffers heavily from electrostatic discharges (also known as ESD) during many steps of the manufacturing process. This ESD can cause shocks to operators, damage electrical equipment and even initiate sparks that start fires.

Harmful Static Build Up in Textiles

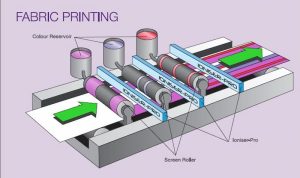

The process of rolling textile fabric at high speeds will always generate increased static charges. These static charges, if left uncontrolled, can build to dangerous levels creating harmful ESD. When leaving rollers, the textile fibres will generate static charges by contact differences of potential amounting to several kilovolts.

The potential difference (similar to voltage) equals the amount of current multiplied by the resistance. You can reduce the differences in potential by either manufacturing anti static material or controlling the generated static with our Ioniser-Pro industrial static control.

We recommend placing our Ioniser-Pro static eliminator bars between the rollers to provide excellent ESD protection. These bars will help prevent ESD from being harmful to your equipment and prevent any ink fly contamination during the printing process from ruining your product.

Computer systems run most industrial textile printing, and these systems can be left vulnerable if not protected by static control equipment. ESD can have a devastating effect on computer systems, permanently damaging the hardware. Textile folding machines will generate a lot of static electricity as they move fabrics around. If this is allowed to persist, then these items will stick to the conveyor system and not travel smoothly.

Anti-Static Textiles

All stages of textile manufacturing generate static electricity, but uncontrolled static during high-quality printing can be disastrous to your product. Any erratic changes in your printing environment will negatively affect your print quality and create colour contamination.

When printing textiles, they are even more susceptible to fires started by ESD. The combination of an already highly charged environment and flammable materials makes installing effective static control vital for your business.

The wool and cotton industries have additional concerns about uncontrolled static generation. The additional static charge generated affects the fibres during the carding and spinning processes. Without effective static control equipment in place, your product will suffer irregularities and weaken the yarns.

Industrial Static Control in Textiles

For you and your staff, we offer a range of ESD prevention straps and accessories made from anti-static textiles. These will protect your team from any potential ESD.

If you’re considering choosing our popular anti-static bars, make sure to get the Ioniser-Pro Cleaning kit. Regular maintenance is essential to ensure that your static bar is working to its utmost efficiency.