Many of our customers in the printing sector are unfortunately very familiar with electrostatic discharge (ESD).

Static is essential for the static printing process. Still, when it’s not controlled, the processes involved can generate vast amounts of uncontrolled static that can affect your product and put your workers at risk of ESD discharges.

Static build-up when printing can cause plenty of problems. Printing processes such as:

– Screen printing

– Pad printing

– and Digital printing

All suffer from an imbalance of electrostatic charge between the ink application and the substrate, which can cause printing defects.

Common Issues with Static Printing

Typical defects include:

- Dust attraction and contamination

- Clogged nozzles

- Overspray

- Ink manipulation and ‘ink fly’ – when static builds up and ink is attracted to the wrong spot or fails to adhere to the location it is meant to

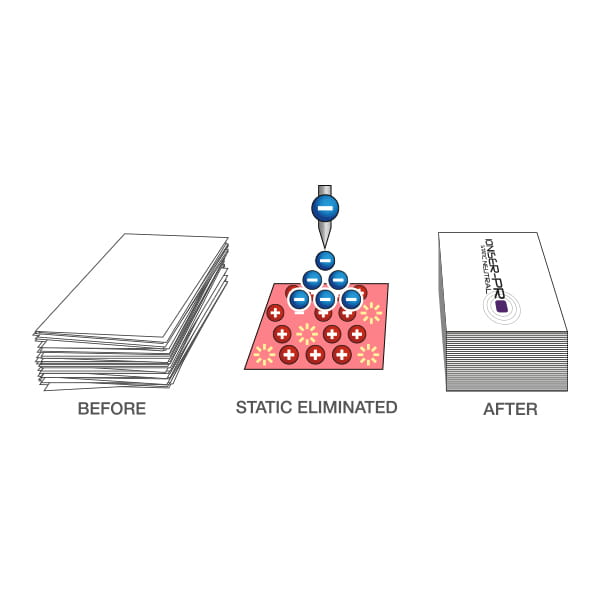

- Substrate cling – when two objects generate a static charge and stick together

- Operator shock – whilst most of the time these shocks are simply an annoyance; they can cause severe health issues and even spark a fire

- Spider webbing, or ink spidering – when ink radiates from the edges of the artwork, causing blurring

- These issues can lead to many rejects, causing costly reprints and production delays

By preparing for these problems with the various anti static solutions we supply online, you can gain peace of mind that your product, staff and business as a whole will function safely and smoothly.

Our Advice For Static Elimination in Printing

We can provide you with effective static elimination equipment for screen printing at Ioniser Pro.

To prevent static build up in standard printing, you can pass the substrate through two Ioniser-Pro static elimination bars at the feeding point. This will neutralise static on both sides of the substrate before printing begins and, if needed, when the finished print is about to be stacked. The substrate will be neutralised by simply passing under the ions emitted by the bar by placing an Ioniser-Pro immediately after the dryer.

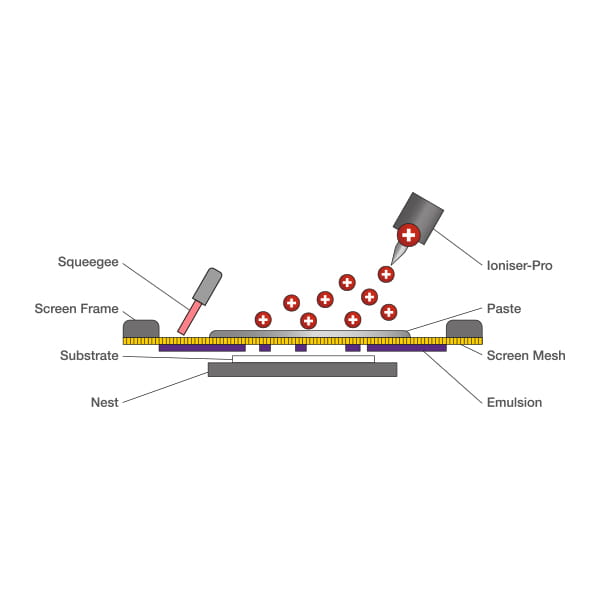

Simply place the product above the screen frame (up to 75mm), the bar will flood the area with ions which will neutralise the charge on an ongoing basis.

area with ions which will neutralise the charge on an ongoing basis.

In pad printing, we recommend that an Ioniser-Pro static elimination bar be placed between the pad plate and the substrate to flood the pad with static neutralising ions while the pad moves from the plate to the substrate.

Our Ioniser-Pro Pro Blow units can also be used by mounting on the walls in an enclosed area. When used, they flood the space with static, eliminating ions.

Ioniser-Pro bars can also be retrofitted to your machinery wherever your static hotspots are.

If you want to know more about any of our other anti static products or are unsure which solution is right for you, please don’t hesitate to contact us today, and one of our experts will answer all your questions.